Modern quality systems rely on trace-ability and accountability throughout the entire process.

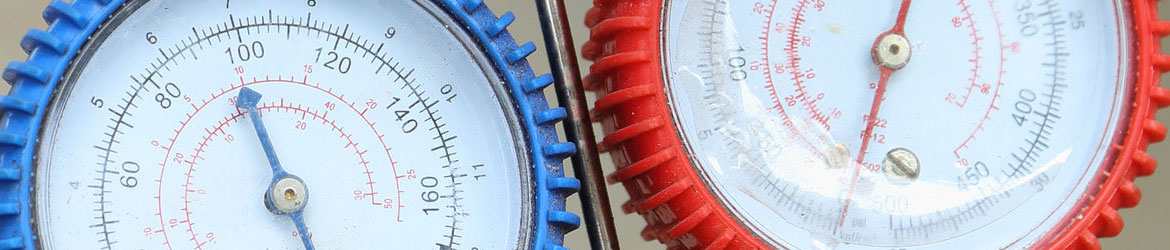

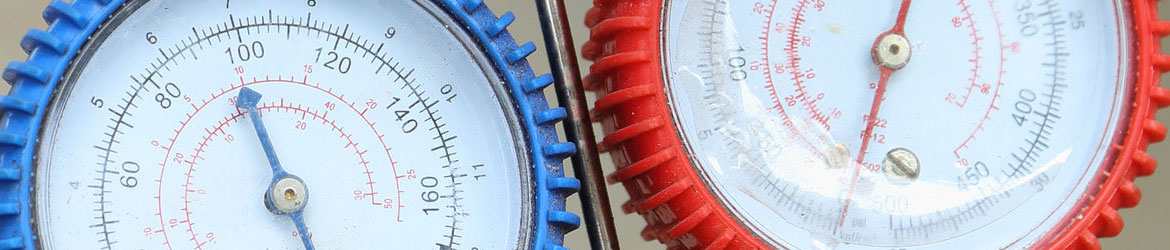

Each Compressortech remanufactured compressor is 100% NLP. (noise, leak, performance) tested. Our computer based test bench converts the raw output data, comparing this information against OEM parameter specifications - like an engineers note-pad.

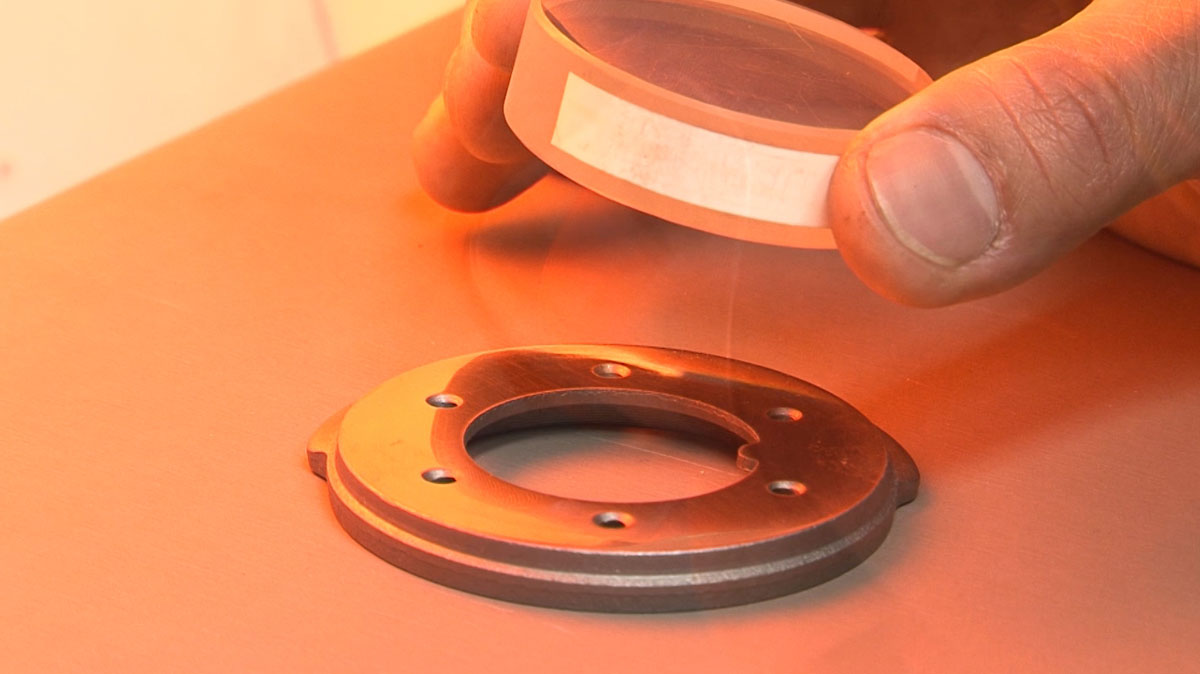

All information regarding the entire remanufacturing and testing procedure for each type of compressor is recorded and stored which allows us to provide 'total traceability and accountability'.

Regular audits are carried out on our entire remanufacturing process.