The most important feature of Compressortech and certainly one of our key strengths, is the ability to manufacture our own production tooling. This undertaking is cost effective and efficient, resulting in substantial savings in both time and money for our customers. Our Tool room is modelled on the world's finest facilities and is in turn responsible for the design of some very unique and special tools and components. This allows Compressortech to remanufacture a wide variety of Automotive Air Conditioning Compressors that function perfectly and provide a long service life.

|

|

|

|

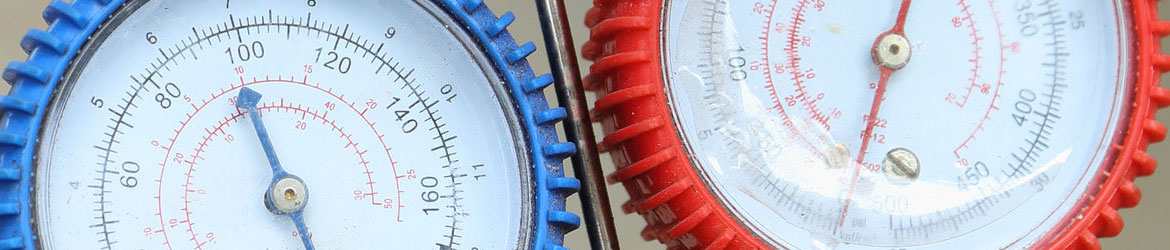

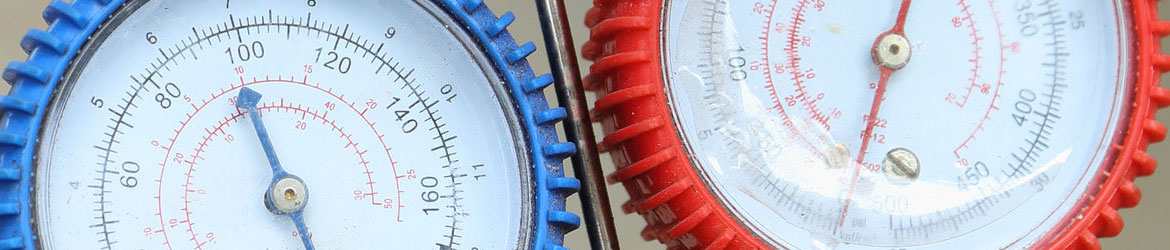

Our Oil Scan Service is used upon any compressor returned to Compressortech. Oil Scan works on the same principle as a doctor uses a blood test to diagnose a patient's condition. As the compressor lubricant travels around the compressor it collects valuable information about its operating conditions. |

||

| This information is extracted from the system oil (like a fingerprint) using sophisticated laboratory analysis at Compressortech's R & D Department. The results generated from the Oil Scan analysis will provide information to diagnose the condition of the faults held within the air conditioning system, which has caused the compressor to fail. This data is recorded and reported directly back to the customer. |

|||

|

|

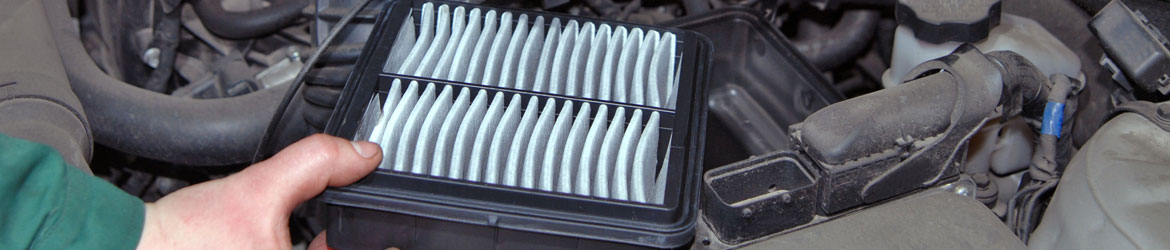

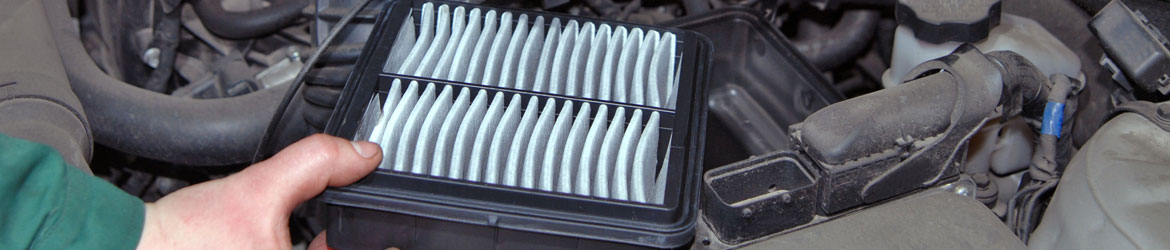

Core is the life-blood of remanufacturing. Without the core we cannot offer an 'off the shelf' Service Exchange Programme. Our core selection process ensures that we use suppliers with the capability to deliver at the same level of quality and service that we expect from ourselves. We have a strict criteria in only sourcing and using the very best OE Core, which in turn allows us to provide a quality product. This is the first critical step in assessing that the raw material is suitable for remanufacturing. Once the Core is approved it is then despatched to the disassembly process area. | |||||

Compressortech's comprehensive Core Bank is updated on a weekly basis to support availability for our 'Service Exchange Programme'. Our Easy Core Return Programme is based on the following condition: the unit is returned in the original box supplied, the core is the same specification as the product purchased, free of external damage and the clutch can turn. Core Policy: A used compressor is not considered a Core unless it can be remanufactured.

|

||||||